Current Issue : Article / Volume 3, Issue 2

- RESEARCH ARTICLE | DOI:

- https://doi.org/10.58489/2836-2276/027

Assessment of Traditional Way of Value Addition Practices on Processing of Milk and Milk Products in Selected Districts of South Omo Zone

1Southern Agricultural Research Institute, Jinka Agricultural Research Center, P.O. Box 96, Jinka, Ethiopia.

Demerew Getaneh *

Demerew Getaneh, Mekete Girma. (2024). Assessment of Traditional Way of Value Addition Practices on Processing of Milk and Milk Products in Selected Districts of South Omo Zone. Journal of Food and Nutrition. 3(2); DOI: 10.58489/2836-2276/027

© 2024 Demerew Getaneh, this is an open-access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

- Received Date: 24-04-2024

- Accepted Date: 01-06-2024

- Published Date: 06-06-2024

Maale, Fumigation, Indigenous, South Omo zone, Preservative plant, Processing, Smoking

Abstract

The study was carried out to evaluate, identify, and characterize various traditional milk preservative plants and investigate their indigenous techniques of handling, processing and preserving in the South-Ari and Maale districts. Data were collected from 196 households by purposive sampling, interviewed using a semi-structured questionnaire, and analyzed using SPSS. More than 12 indigenous preservative plants that were commonly used by the respondents were identified and collected. In the South-Ari district all (100%) respondents used plant species of Lippia adoensis Hochst, Cordia Monoica Roxb., Leucas Deflexa Hook.f and Satureja Paradoxa, while in the Maale district 63.5% of the respondents used only fresh Balanites Aegyptiaca leaves to clean the milk utensils while 36.5% used fresh leaves of Solanum Incanu, Hoslundia Opposita, Balanites Aegyptiaca, Lantana Camara, and Celosia Trigyna. as washing milking and storage vessels. About 96% of the plants frequently used to smoke milk equipment in the South-Ari district were Clerodendrum Myricoides, Eucalyptus Globulus and Olea Africana while almost all (99%) households in the Maale district smoked milk utensils with Balanites aegyptiaca, Solanum Incanum, Lantana Camara, and Ocimum Forskolei Benth. The application methods were through rubbing, burning, and both burning and immersion in the milk vessels. The main cause of the loss of milk after harvest in the South Ari (93.7%) and Maale (40%) districts was milk spoilage. The majority of the 92% in South-Ari and 66.7% in Maale respondents minimize milk spoilage by consuming early or selling to the market. It could be concluded that the herbal plants identified in this study required further examination and their impact on the health of consumers should be studied in detail.

Introduction

Ethiopia has the largest livestock population in Africa, with an estimated 70 million head of cattle, 42.9 million sheep, 52.5 million goats, 2.15 million horses, 10.80 million donkeys, 0.38 million mules, and about 8.1 million camels [1]. Livestock farming is an important and integral component of agriculture and rural livelihood in the country, contributing approximately 17% to 25.3% of the national gross domestic product (GDP) and 39% to 49% of agricultural GDP and over 50% of household income [2], and 12%–15% of the export earnings and provides employment for about 60%–70% of the population [3]. In Ethiopia, dairy cows are estimated to be around 7.56 million and milking cows are about 15.04 million heads [1]. Milk productivity is very low and annual per capita milk consumption is very low, estimated at 20 liters [4]. Dairying is one of the livestock production systems practiced almost throughout the world, including Ethiopia, involving a large number of small, medium or large scale, subsistence or market-oriented farms [5]. Milk is well known to be produced, processed, and utilized in different parts of Ethiopia. Many Ethiopians consume dairy products either as fresh milk or in fermented or soured form [5]. Milk is a complex mixture of compounds that is, water, fat, protein, lactose, enzymes, minerals, organic acids, and vitamins [6]. Milk composition is influenced by factors that are specific to a cow and its environment. These factors are breed, age, health status, lactation stage, diet, intensity of management, milking interval, and ambient environmental temperature and seasonality, which influence feed availability [7] [6].

Raw milk is one of the most suitable media for the growth of a wide variety of bacteria, especially immediately after milking, when it is almost at body temperature. It is well known that milk is highly perishable by nature, and therefore it requires adequate care from production to consumption, especially handling during milking, collection and subsequent storage, transportation, chilling, processing, and distribution [8]. In Ethiopia, there are no standard hygienic conditions followed by producers during milk production. Hygienic conditions are different according to the production system. In most cases under smallholder conditions, common hygiene measures taken during milk production, especially during milking, are limited to letting the calf suckle for a few minutes and/or washing the udder before milking [9]. However, the quality of the water used for cleaning purposes (washing of the udder, milk equipment and hands), however, is not secured [10]. Therefore, milk production under Ethiopian smallholder conditions can generally be characterized as unhygienic. Identifying the causes of post-harvest loss of milk and dairy products is necessary to find solutions to the problem and justify interventions aimed at reducing or eliminating these losses [8].

The use of traditional plants is of great importance in many societies, including most rural African communities [11]. In addition to providing building materials, food, weapons, and other commodities, plants are especially important as traditional medicines [12]. Traditional plants are used as food, building and construction materials, fuel, human and veterinary medicine, and fodder [13]. Plants also find important uses in ceremonies and rituals, as well as brushing and chewing, to pass the time and exercise the jaws. Small-scale milk-producing households have adopted different practices to mitigate post-harvest milk losses. Smoking milk handling equipment using different plant materials and milk processing traditionally are among the mechanisms used to minimize post-harvest losses [8]. In Ethiopia, many farmers, particularly dairy producers, have their own traditional practices of preserving milk products to improve the quality of the preservation and value addition of locally produced dairy products through the hygienic practice of milk and milk handling utensils by applying locally grown plants through their own processing ingenuity and experience. Customers provide better returns to the producer through value additions. Befekadu et al. [5] reported that dairy processing plants are few, that much of the milk produced by rural smallholders is processed on farms using traditional technologies and that milk processing is based on sour milk. On the other hand, small-scale milk producers and processors are also using the addition of plant materials directly to milk products in order to alleviate the problem of milk and milk products' spoilage before consumption. However, there are different types of plants that are used to smoke and clean milking, storing, processing, and marketing utensils in different parts of the country. The identification and characterization of these traditional herbs and the determination of the active ingredients and the methods of use could be very crucial in developing appropriate technologies for the handling and preservation in the country [14].

In the South Omo zone, pastoral and agropastoral households have practiced different methods to alleviate postharvest milk losses. The use of herbal plants for the preservation of milk by fumigating and washing milk vessels is a common practice for a long period of time. However, the main causes of the milk spoilage problem, their cultural perception and the traditional methods to preserve milk and its products were not well studied or documented. In addition, all herbs used locally are considered effective in improving the microbial safety and quality of milk. However, there is no documented study on the role of these milk preservative plants in these areas. The present study aims to assess, identify, and characterize different traditional or indigenous knowledge on milk preservative plants used by the community; and to investigate their indigenous techniques of handling, processing, preserving, application, as well as postharvest loss of milk and the traditional mitigation system in the South-Ari and Maale districts in the South Omo Zone.

Materials and Methods

Description of study areas

The study was carried out in milk producing potential areas of the South Ari and Maale districts. The South-Ari district covers an area of 1520 km2 and has a human population estimated at 219,708 and a population density of 144.4 persons per km2. The district is divided into 48 rural and 3 urban peasant associations (PAs). Generally, the altitude of the district ranges between 850 - 2800 m above sea level. The district is divided into three traditional agro ecologies; Dega, Woina dega, and Kola which cover 25, 39, and 36 percent of the total area, respectively. The rainfall pattern in the area is bimodal, the mean annual rainfall and temperature range between 100-1600 mm and 15 and 35o c, respectively. The Maale district covers an area of 1432 km2 and the population density is very sparse with an estimate of 66 persons per km2. The district has 23 rural kebeles (villages) and one urban kebele. The altitude ranges between 600-1500 m.a.s.l., the area is situated between 5.080N -6.010N latitude and 36.30E -370E longitude. It comprised 40% midaltitude, which ranges from 1000-1400m a.s.l land and 60% lowlands which have been ranging from 605-999 m above sea level. The mean annual rainfall ranges from 800-1200mm with an annual temperature between 18-35oC [15].

Sampling Procedure and Sample Size Determination

For this particular study, the South Ari and Maale districts were purportedly selected on the basis of their potential for milk production. The multistage stratified random sampling method was used to select locations within districts and households. Consequently, from the total kebeles in the two districts in the first stage, the potential kebeles in milk production were selected purposely with the assistance and information obtained from the Agriculture Office. In the second stage, out of the potential kebeles, six kebeles were randomly selected (three kebeles from both districts). In the third stage, the number of sample households from each sampled kebeles was determined from the recent lists of households using proportional to size. Consequently, a total of 196 dairy households, 100 from the south-Ari district and 96 from the Maale district, were individually interviewed using a semi-structured questionnaire. To determine the appropriate sample size, the basic factors to be considered are the level of precision required by the users, the confidence level desired, and the degree of variability. Thus, it was determined using a simplified formula provided by Kothari [16].

The sample size was determined using the following formula

n =

Where: n: was the sample size for a finite population N: the population size which was the number of households in the districts; p: population reliability (or frequency estimated for a sample of size n); p was 0.5 which was taken for all the population of developing countries and p + q= 1 e: the margin of error considered was 7%. Zα /2: normal reduced variable at 0.05 level of significance and z 1.96. The sampling unit here was households, and the sampling frame was all the six kebeles household lists that were available in the kebeles. Therefore, based on the above formula, the number of households to be sampled was determined as 196.

Data Sources and Method of Data Collecting

A semi-structured questionnaire was prepared to collect information. The questionnaire was pre-tested prior to the actual survey, and relevant secondary data was collected from the Internet, the agricultural office, and written documents. Information on the type of plant materials used, preparation of plant extracts and the technique of milk preservation was obtained by individual observation and focused discussions guided by a checklist. The three age and gender groups of the respondents involved in the study were older, women, and youth.

Collection of preservative plants

The collections of preservative plants from the districts were made through discussion with the holders of traditional milk preservative and processing knowledge. Milk preservative plant species and herb types commonly used by communities for milk processing and preservation through fumigation and smoking were identified, collected and cleaned with the help of the knowledge holders in the local community.

Plant species identification

The collected plant samples were coded by their local names and transported by a plant presser and a plastic bag to avoid drying, as well as for species identification purposes. After collection and drying, botany specialists in the Department of Biology of Addis Ababa University College of Natural and Computational Sciences identified the samples for their scientific names.

Statistical analysis

The collected data were coded; entered into a computer and analyzed qualitatively and quantitatively using SPSS version 23.0 software (IBM, USA) for all statistical analyzes to compute descriptive statistics for the variables. Descriptive statistics were used to present the results. The Chi-square (χ2) test was used to compare the proportions of categorical variables among the districts. A t-test was used to compare mean differences that were considered significant at p< 0>

Results and Discussion

Plant species

The preservative plant species utilized by milk producers as milk vessel fumigation and smoking to preserve milk quality were identified. Plants / herb species were selected after detailed interviews and consultations with the local knowledge persons or elders of each district. The plant species used commonly by the communities to reduce milk spoilage and keep milk better quality or aromatic were collected and identified. The indigenous milk preservative plant species used in study districts that are used most frequently by dairy producers were observed and identified. These selected plant species were botanically classified into the Verbenaceae, Lamiaceae, Rubiaceae, Boraginaceae, and Amaranthaceae families. These plants which were used to process and preserve milk through the smoking and fumigation of milk vessels were identified and collected from the field that is frequently used by the South-Ari and Maale communities with the perception of improving flavor, providing aroma, and extending the shelf-life of their milk products. To fumigate and smoke the milk utensils, the households used different selected plant parts such as branch/leaf, stem, root and together with the fresh or dried forms of each other.

Types of herbal plants used to wash and smoking milk utensils

The plant species used for the cleaning and smoking purpose of milking equipment and fermenting utensils are presented in Table 1. Almost all respondents in both districts used locally grown milk-preserving plants for washing and fumigating or smoking their milk utensils which were used for milking, milk storing, and processing to increase the fermentation period, increase shelf-life of milk products, and to provide better flavor. Similarly to this result Tsedey and Bereket [8] reported that flavoring and smoking using different parts of plant materials were used to prolong the shelf life of milk and milk products in the Dilla, Hagere Selam, Dale and Hawassa districts of southern Ethiopia. Milk utensils were thoroughly washed using different plants and washing techniques before smoking [17] in South Wollo areas of Ethiopia. However, the cleaning plants used for washing and smoking of milking equipment differ from place to place and even from household to household based on their preferences [18].

In the Ari district, almost all (100%) respondents used plants such as Tsisi (Lippia adoensis Hochst. ex Walp.) (fresh leaves), Ashikilash (Cordia monoica Roxb) (fresh leaves), Ledi (Satureja paradoxa (Vatke) Engl. ex Seybold) (fresh leaves) and Ras kimir (Leucas deflexa Hook.f) (fresh leaves) as washing of milk vessels. In particular, Ashikilash leaves (Cordia monoica Roxb) are used for heavy and soiled milk utensils because it has a glassy paper-like texture that loosens the utensils. Respondents mentioned that Arkinity (Pentas schimperiana (A. Rich.) Vatke) (grass type) and Girawa leaf (Vernonia amygdalina) by mixing with boiling water and salt they give to milking cows to increase milk yield. Boiling of the Girawa leaf will remove its bitterness and prevent the bitter taste of the milk. When animals feed on the leaves of Girawa, their blood becomes bitter, thus protecting themselves from different flies and insects landing on them [19].

In the Ari district, the most frequently used plants (96%) by respondents for smoking milk equipment were Dumpkien (Clerodendrum myricoides (Hochst.) Vatke) (dried root), Nechi bahirzaf (Eucalyptus globulus) (dried fruit), Ras kimir (Leucas deflexa Hook.f) (dried leaves) andWoira (Olea Africana). These plant types, in addition to their disinfectant nature for churners, give a tasty and good flavor to milk products due to the scent scenario of the plants. The respondents assumed that the milk storage was fumigated by dropping it with a fumigation plant and the wood was kept burning until it was finished. These traditional smoking practices through burning wood chips of particular plant and shrub species were used to minimize microorganisms, thus increasing the shelf life of milk. This finding was in line with Abebe et al. [20] and Tsadkan & Amaniel [21] who reported milk utensil devices are washing and smoking using various species of aromatic herbs. In addition to serving as a natural aroma and flavor, it is used to prevent milk spoilage and extend its shelf life until consumed. The finding was also consistent with the report of Abebe et al. [9] and many other authors who reported that the most apparent species of woody plants such as Olea africana, Acacia busia and Eucalyptus globules were used to smoke milk vessels to improve the quality of milk product. Befekadu et al. [5] also stated that Olea africana was the major smoking in the Borena areas. Previous study by Kassahun [22] in Ada’a Woreda stated that among the different species of milk-preserving plant and herbs Olea Africana (Olive), Eucalyptus globulus (Eucalyptus), Lippia adoensis (Koseret), Ruta chalepensis (Rue), Ocimumbasilicum (Basil) and Thymus vulgaris (Thyme) were frequently used in Ethiopia. These plant and herb types have flavoring and aromatic sounds and therefore could be extending the shelf life of milk products and improving their taste. Similar results for smoking milking utensils were also reported by Tigist [23] and Sale et al. [24].

Similarly, in Maale district, 63.5% of the respondents used fresh Kuzi leaves (Balanites aegyptiaca) withgravel and water to clean or wash milk utensils. The remaining 36.5% of the respondents used fresh leaves of Garenti (Solanum incanum), Lisho (Hoslundia opposita Vahl), Kuzi (Balanites aegyptiaca), Enaro (Lantana camara), gravel, and water as cleaning milking and storage utensils. About 99% of dairy cattle keepers in Maale district were smoking their milking utensils with different species of aromatic plants such as Kuzi (Balanites aegyptiaca) Garenti (Solanum incanum), Enaro (Lantana camara), Aftesha (Ocimum forskolei Benth.), Lisho (Hoslundia opposita Vahl), Mazmayilo (Celosia trigyna L.). The selection and usage of these preservative plants depend on the accessibility and preferences of the user. The use of these plant parts for fumigation varies from one location to another and even from one household to another. About 58% of the households in the South Ari district used dried leaf, root and crust parts of the plant and 29% only dried leaf and 13% used dried root and crust parts of the plant. In Maale district, the majority (95.8%) of households used dried leaf, root, and crust parts of the plant, while only 4.2% used only dried leaf as milk equipment fumigation.

In both the South-Ari and Maale districts, the purpose of the fumigation of the milking equipment was to improve flavor (94% South-Ari and 75% Maale), prevent milk spoilage and increase shelf life (4% South-Ari and 20% Maale) and ensure better cleaning (2% South-Ari and 5% Maale). The current study was in close accordance with the findings of Tsadkan & Amaniel [21] and Fikernehe et al. [25] in Mekelle milk shed and in the Mid-rift Valley area, respectively. Another report carried out by Shambel et al. [26] showed that such types of plant leaves, due to their high level of metabolized nature, are widely used for the production of medicated ingredients in addition to traditional aspects of milk hygiene and processing advantages. Regarding smoking time, 78.3% of South Ari and 81.2% of Maale district smoked their milk utensils before and after use, while 15% and 13% smoked before use; 6.7% and 5.8% smoked after use, respectively. The study by Admasu [27] indicated that, indigenous knowledge of the practices of washing and smoking milking utensils through burning wood chips of particular trees or shrub species has boosted providing a tasty and scented nature in the disinfection of milk utensils and minimizing microorganism growths.

Table 1: Plants and the way used to wash and smoke / fumigate milk vessels

| Descriptor | Districts | |||

| South-Ari (%) | Maale (%) | Overall (%) | X2 | |

| What are milk vessel washing tools or plant part? | 0.00** | |||

| Garenti(Solanum incanum), Lisho (Hoslundia opposita Vahl), Kuzi (Balanites aegyptiaca), Enaro (Lantana camara), gravel + water | 0 | 36.5 | 17.9 | |

| Only Kuzi (Balanites aegyptiaca) with gravel and water | 0 | 63.5 | 31.1 | |

| Tsisiy (Lippia adoensis Hochst. ex Walp.), Ras kimir (Leucas deflexa Hook.f), Ledi (Satureja paradoxa (Vatke) Engl. ex Seybold) | 100 | 0 | 51 | |

| Do you practice smoking of milking utensils? | ||||

| Yes | 97 | 100 | 0.12 | |

| No | 3 | 0 | ||

| What are smoking materials? | 0.00** | |||

| Dumpkien (Clerodendrum myricoides (Hochst.) Vatke), Eucalyptus (white-fruit), Ras kimir kimir (Leucas deflexa Hook.f) | 96 | 0 | 48 | |

| Woyra (Olea Africana) | 4 | 1 | 2.5 | |

| Kuzi (Balanites aegyptiaca) dried leaf/root/crest and dried Gerenti (Solanum incanum) | 0 | 99 | 49.5 | |

| What is the purpose of smoking? | 0.00** | |||

| For good flavor | 94 | 75 | 84.5 | |

| Ensures better cleaning | 2 | 5 | 3.5 | |

| Prevent milk spoilage | 4 | 20 | 12 | |

| Which plant parts are used for fumigating? | 0.00** | |||

| dried leaf | 29 | 4.2 | 16.4 | |

| dried root and crust | 13 | 0 | 6.6 | |

| dried leaf, root and crust | 58 | 95.8 | 77 | |

| When do you smoke milk utensils? | 0.06 | |||

| I smoked before using | 15 | 13 | 14 | |

| I smoked after using | 6.7 | 5.8 | 6.25 | |

| I smoked before and after using | 78.3 | 81.2 | 79.78 | |

The value observed between the two districts was significantly different at * (X2<0>); ** (X2<0>); X2= Pearson Chi-square.

Use and application technique of herbal plant parts

The indigenous plants and their part used to wash and smoke milk utensils and use the technique are presented in Table 2. The application methods of these plant species were through rubbing, burning, plus immersing the parts of plants inside the milk utensils and spreading smoking all parts of the storage properly. Finally, after the plant’s stem smoking was also employed on the inside part of the storage, then fresh milk was added to it. This finding is agreed with Alemu & Girma [17] in South Wollo Zone. A recent study by Shambel et al. [26] observed that the uses of the different methods depend on the type of plant and accessibility used in the areas. A similar study was conducted by Lemma et al. [14] who revealed that smoking of milk vessels is frequently used to provide a pleasant taste of the products. Many milk preserve plant species are classified into woody trees, shrubs and herbs [26] [28].

Table 2: Indigenous plant and its part used for washing and smoking milk utensils and using the technique

| Districts | Name of the plants | Form and part used | Application way | Local use | |

| Local name | Scientific name | ||||

South -Ari

| Tsisiy | Lippia adoensis Hochst. ex Walp. | Fresh leaf | Rubbing | Washing |

| Ashikilash | Cordia monoica Roxb. | Fresh leaf | Rubbing | Washing | |

| Ras kimir | Leucas deflexa Hook.f | Fresh leaf | Rubbing | Washing | |

| Ras kimir | Leucas deflexa Hook.f | Dried leaf | burning | Fumigation | |

| Woira | Olea Africana | Stem | burning | Fumigation | |

| Ledi | Satureja paradoxa (Vatke) Engl. ex Seybold | ||||

| Dumpkien | Clerodendrum myricoides (Hochst.) Vatke | Root | burning | Fumigation | |

| Nech bahir zaf | Eucalyptus globulus | Fruit | Sift and burning | Fumigation | |

| Arkinti | Pentas schimperiana (A. Rich.) Vatke | Grass | Steaming with water feeding | Increasing milk yield | |

| Girawa | Vernonia amygdalina | Fresh leaf | Steaming with water feeding | Increasing milk yield and anti-fly/ insects | |

| Tena adam | Ruta chalepensis | Fresh leaf | Immersing | Flavor | |

| Maale | Kuzi + gravel | Fresh leaf | Rubbing | Washing | |

| Kuzi | Balanites aegyptiaca | Dried leaf, crust and root | burning | Fumigation | |

| Woyra | Olea Africana | Stem | burning | Fumigation | |

| Aftesha | Ocimum forskolei Benth. | Dried leaf | burning | Fumigation & washing | |

| Lisho | Hoslundia opposita Vahl | fresh leaf | Rubbing | Washing | |

| Garenti | Solanum incanum | fresh leaf | Rubbing | Washing | |

| Garenti | Solanum incanum | dried leaf, crust and root | Burning | Fumigation | |

| Mazmayilo | Celosia trigyna L. | fresh leaf | Rubbing | Washing | |

| Enaro | Lantana camara | fresh leaf | Rubbing | Washing | |

Source: Owned Survey

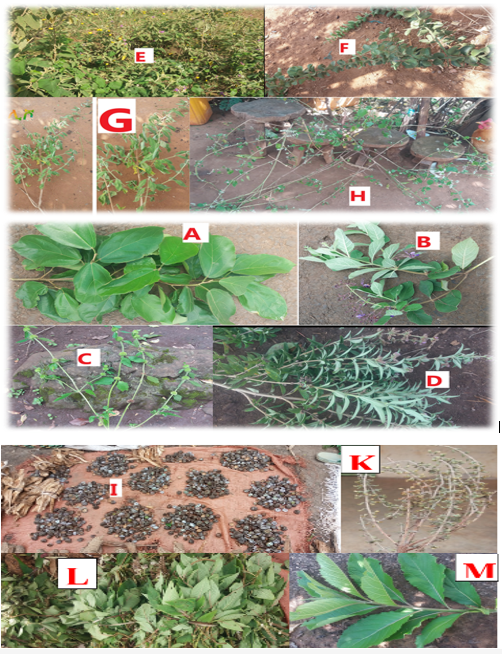

Fig 1: Types of herbal plants used for washing and smoking milk utensils in the districts of South-Ari and Maale districts (A,B,C,D,E,F,G,H,I,K,L,M; Ashikilash, Dumpkien, Ras kimir, Tsisy, Garenty, Kuzi, Lisho, Mazmayilo, Nechi bahirzaf fruit, Aftesha, Arkinity and Girawa, respectively).

Milk post-harvest loss and mitigation strategy

The causes of post-harvest loss of milk and its minimizing methods are illustrated in Table 3. The main cause of milk post-harvest losses in the South Ari (93.7%) and Maale (40%) districts is milk spoilage and the remaining 3.1% and 22percentage caused by milk spillage in both districts, respectively. About 23% of Maale milk post-harvest loss caused by poor hygiene. About 78.7% of milk contamination was caused by poor milk handling practices [21]. A similar report was noticed by Tsedey & Asrat [29], who reported that inadequate milk handling were observed as the main reason for milk spoilage in the Hawassa and Yirgalem districts. Different types of fermented dairy products are traditionally prepared, processed, and consumed by many Ethiopian people. Therefore, the preservation of milk and its products is a vital component of safe use.

Regarding the milk spoilage mitigation strategy, households in the studied areas use various indigenous methods to diminish milk spoilage and post-harvest loss. The majority (92% in South Ari and 66.7% in Maale) of the respondents minimize the spoilage of milk by eating it early or selling it to the market. The rest (7% and 2%) prevent milk spoilage by keeping it in a cold place, respectively. About 31.3% of dairy producers in Maale district minimized milk spoilage by keeping and cleaning milk equipment regularly before and after use. Trends to prevent milk spoilage in the country are limited to boiling directly after milking or using lactose through bacteria fermentation and sanitizing methods [9]. In support of this idea, Gagara et al. [30] and Getaneh [19] reported that preservation and care of milk quality through the processing of milk into other products such as yoghurt, cheese, butter, buttermilk, and whey are common practices in the absence of refrigeration.

About 87% in the South-Ari and 98% in the Maale districts have not practiced adding different spices before and after processing milk and its product. Only 13% and 2% of dairy processors practiced adding spices before and after processing milk and its product in both districts, respectively. The types of spices added to the milk product were Tena Adam (Ruta chalepensis) in yogurt and cheese, Zingibil, Besobila, and Erdi in cheese. Immersing of spice ingredients in milk and its product varies from household to household based on accessibility, experience, and interest. These spices are served as coloring agents (for butter to be yellowish), add value and shelf life (for yogurt and butter), and tasty and flavor for marketing demand (for cheese) to be attractive. The present result is in parallel with the findings of Abraha [31] and Abebe et al. [9].

Table 3: Causes of post-harvest milk loss and its minimizing methods

| Descriptor | Districts | |||

| South-Ari (%) | Maale (%) | Overall (%) | X2 | |

| What are the causes of milk postharvest loss? | 0.00** | |||

| Spoilage | 93.7 | 40 | 67.4 | |

| Spillage | 3.1 | 22 | 12.55 | |

| Long fasting season | 3.1 | 14 | 8.55 | |

| Poor hygiene | 0 | 23 | 11.5 | |

| Do you add different spices before and after processing milk? | 0.00** | |||

| Yes | 13 | 2 | ||

| No | 87 | 98 | ||

| What are the methods you used to minimize milk spoilage? | 0.00** | |||

| keep milk in a cold place | 7 | 2 | 4.5 | |

| Consuming/selling early before spoilage | 92 | 66.7 | 79.6 | |

| Always keep and clean milk equipment | 1 | 31.3 | 15.3 | |

The value observed between the two districts was significantly different at * (X2<0>); ** (X2<0>); X2= Pearson Chi-square.

Sanitary practices for the udder and hands

The milking and hygiene practice is presented in Table 4. The majority of 98% and 88.5% of the respondents carried out adequate hand washing practices before milking with water in the South Ari and Maale districts, respectively. The current result was comparable with reports from different parts of the country [27] [32] [33] [24] [23] which they noticed as they wash their hands before milking. The findings by Fortunate [34] contrarily noticed that more than 60% of farmers did not clean their hands, wash cow teats and clean their animal sheds before milking in Tanzania. According to the report of Zelalem [35] and Abebe [32] milkers' hands can be an important source of milk contamination, thus maintaining good personal hygiene and milkers should be in good health during milking operations. Contaminated milk is responsible for up to 90% of all dairy-related diseases in humans [34]. Aysheshim et al. [36] also indicated that milk producers should follow hygiene practices during milking and handling, before delivery to consumers or processors. According to Blowey and Edmondson [37], poor milking practices, dirty udders or teats, damaged teats, and poor operator hygiene can all lead to increased contamination of raw milk. Befekadu et al. [5] reported all the respondents practiced washing milk equipment used to milk, store, and process milk prior to milking in the Borena zone. If the hygienic standards of production and handling are poor, the quality of milk storage would be very poor due to high ambient temperatures and there will be a very high risk of spoilage [38]. So, milk should have a normal composition, not adulterated, and be produced under hygienic conditions [39].

Most (78% and 90.6%) of the respondents in the study areas did not practice washing the milk cow udder before milking, but only a few respondents (22% and 9.4%) practiced washing the milk cow udder before milking in the districts of South Ari and Maale, respectively. This result was comparable with the study of Abebe et al. [20] who report that none of the respondents practices washing their cow’s udder before milking in the Gurage zone, Ezha wereda. The milking practices of the current study were similar to Befekadu et al. [5] who reported that none of the respondents practice hand washing and cow udder cleaning before milking in the Borena zone. In addition, the result was also similar to Gatwech [40] who reported washing of teats is not practiced by almost all (98.7%) respondents in agricultural and urban producers (96.2%) in Gambella. This result contradicts the reports of Admasu [27]; Alemu and Girma [17]; Abebe et al. [32]. The respondents believed that allowing the calves to suckle prior to milking is sufficient to clean the teats. A reported result by Alemu and Girma [17] in South Wollo Zone indicated that women dip their fingers into the milk bucket and moisten the milk teats of the cow to facilitate milking. A recent study by Tigist [23] established that during milking, respondents use calves as stimuli and calves suckle their dam for an average of one to three minutes. Therefore, the production of high quality milk should be a priority for long-lasting good quality end products and for the marketing of value-added products [38]. Happy [41] reported that 94.6% of the respondents did not clean the cows' teat before milking in Kilosa and Mvomero districts of Tanzania.

This practice may allow for microbial contamination of milk from the milker’s hand. The lack of proper cleaning of the udder could affect milk quality and have a significant concern for public health [42] [5]. Furthermore, pre-milking the udder is important to remove both visible dirt and bacteria from the outer surface of the udder [27]. According to Blowey and Edmondson [37], poor milking practices, dirty udders or teats, damaged teats, and poor operator hygiene can all lead to increased contamination of raw milk. The higher microbial loads observed in raw milk could probably be due to lack of knowledge about clean milk production, the use of unclean milking utensils and plastic containers to collect and keep milk, initial contamination of the milk from either the cow's milk or the milkers’ hand and the poor hygiene quality of the milking area, as well as further contamination during transportation. Befekadu et al. [5] also indicated that milk producers should follow hygiene practices such as clean utensils, washing the hands of milkers, washing the udder, use of individual towels during milking and handling, before delivery to consumers or processors.

Milk Utensil Hygiene and Milking Practice

Milk utensil hygiene and milking practices are presented in Table 4. The study revealed that in the districts of South Ari and Maale, about 94.9% and 93.7% of the households cleaned their milking vessels using warm water and fumigated on them, while the remaining 5.1% and 6.3% cleaned without water only fumigating with herbs, respectively. Most of the respondents washed their milking utensils without detergent, such as soap. A probable reason utensil, especially calabash, due to their spongy nature, are not easily cleaned with detergent and cleaning utensils with soap is not recommended due to its smell felt later on felt in the milk [30]. A similar report was noticed by Tigist [23], who reported respondents to milk their cows in their barn in the south Gondar zone, noticed a similar report. About 97.4% of the respondents milked their cows in the morning and evening (two times per day) in both districts. Many research findings on milking practice twice a day were similarly stated by Sisay [43]; Ulfina et al. [44]; Lencho and Seblewongel [33]; Tigist [23].

Table 4: Hygiene and milking practices of milk utensils (%)

| Activities | Districts | |||

| South -Ari (%) | Maale (%) | Overall (%) | X2 | |

| Do you washing your hand before milking? | 0.03* | |||

| Yes | 98 | 88.5 | 93.25 | |

| No | 2 | 11.5 | 6.75 | |

| Do you wash cow udder/teats prior to milking? | 0.03* | |||

| Yes | 22 | 9.4 | 15.7 | |

| No | 78 | 90.6 | 84.3 | |

| Do you have a separate and clean milking place? | ||||

| Yes | 76 | 29.2 | 53.1 | 0.00** |

| No | 24 | 70.8 | 46.9 | |

| Frequency of milking (per day) | 0.03* | |||

| Once | 5.1 | 0 | 2.6 | |

| Twice | 94.9 | 100 | 97.4 | |

| How do you clean milk equipment? | 0.4 | |||

| Only fumigating with herbs | 5.1 | 6.3 | 5.6 | |

| Washing with warm water and fumigating | 94.9 | 93.7 | 94.4 | |

The value observed between the two districts was significantly different at * (X2<0>); ** (X2<0>); X2= Pearson Chi-square.

Conclusions

This finding said that all milk producers used their traditional milk utensils for milking, storing, and processing purposes. Many households used different herbs and milk preservatives grown locally to add value and provide better flavor and taste of milk and milk products. The aim of this is to extend the shelf life of milk and increase the fermentation time by washing and fumigating its milk equipment. They minimize product spoilage during storage and ensure better cleaning. Among the main preservative plants utilized for flavoring and preservation of dairy products in the studied districts were Kuzi (Balanites aegyptiaca) (fresh leaf), Tsisiy (Lippia adoensis Hochst. ex Walp.), Ashikilash (Cordia monoica Roxb.), Ras kimir (Leucas deflexa Hook.f), Enaro (Lantana camara) and Garenti (Solanum incanum) and the most commonly used trees and herbs types for the smoking of milk vessels were Dumpkien (Clerodendrum myricoides), Kuzi (Balanites aegyptiaca) (dried leaf), Nech bahirzaf (Eucalyptus globulus), woira (Olea Africana). These plant species are used for cleaning or washing milk utensils in the form of fresh or dried leaves, stem, fruit, and root. The application methods were through rubbing, burning, immersing, and mixing of each other inside part of milk storage to spread the smoker into the storage properly. Based on this finding, identified plant species would require further examination, the active ingredients, and their efficiency to save the milk product for an extended time without perishables. Their effectiveness on the desirable and/or undesirable microorganisms and influence on the body of consumers should be studied. It should evaluate the quality of preserved milk with these ingredients as milk storage fumigators and their effectiveness in minimizing milk spoilage. Many important indigenous plants are at an endangered level and gradually degraded through deforestation for farming land, expansion of urbanization, and climate change. Therefore, it should be conserved for sustainable use.

Authors' Contributions

Both authors prepared the concepts, wrote the proposal, collected data in the field, reviewed and edited the proposal and manuscript, analyzed and wrote the full manuscript. Both authors contributed equally.

Data availability

All data analyzed in this study are available in the text, and raw data can be obtained from the corresponding author upon request.

Acknowledgments

The support gained from Pastoral, Agro-pastoral, special support requiring regions (PAP) and the Ethiopian Institute of Agricultural Research (EIAR) for their financial funding. The authors also express sincere gratitude to the households in the South Ari and Maale districts who participated in providing information and sacrificed their values. Furthermore, the staff of the Addis Ababa University Department of Biology and Botany specialists is highly acknowledged for their support in identifying the scientific names of sample plants. Finally, the heartfelt appreciation is deserved for Mr. Denbela Hidosa, Addisu Tadele, and Bizuayehu Ayele for their help in the data collection process.

Competing Interests

The authors declare no conflict of interest.

References

- CSA 2021. The Federal Democratic Republic of Ethiopia Central Statistical Agency Agricultural Sample Survey 2020/21 [2013 E.C.] Volume II Report on Livestock and Livestock Characteristics (Private Peasant Holdings). Central Statistical Agency (CSA) Statistical Bulletin 589. Addis Ababa, Ethiopia.

- Shapiro, B. I., Gebru, G., Desta, S., Negassa, A., Nigussie, K., Aboset, G., & Mechale, H. (2017). Ethiopia livestock sector analysis: A 15 year livestock sector strategy. ILRI Project Report.

- Tegegne, A., Gebremedhin, B., Hoekstra, D., Belay, B., & Mekasha, Y. (2013). Smallholder dairy production and marketing systems in Ethiopia: IPMS experiences and opportunities for market-oriented development. IPMS Working Paper.

- Barry, S., Getachew., G., Solomon., D., Asfaw., N., Kidus., N., Gezahegn, A., & Henok, M. 2017. Ethiopia livestock sector analysis: A 15- year livestock sector strategy’, ILRI Project Report, Nairobi, Kenya: International Livestock Research Institute (ILRI).

- Teshome, B., Wassie, M., Ayinalem, E., & Tefera, G. (2019). Traditional knowledge of milk production, processing and utilization in Borena Zone, Ethiopia. World Journal of Dairy & Food Sciences, 14(2), 210-221.

- Schwendel, B.H., Wester., T.J., Morel., P.C. H., Tavendale., M. H., Deadman, C., Ondieki, G. K., Ombui, J. N., Obonyo, M., Gura, Z., Githuku, J., Orinde, A. B., & Gikunju, J.K. 2017. Antimicrobial residues and com-positional quality of informally marketed raw cow milk, Lamu West Sub- County, Kenya, 2015. The Pan-African Medical Journal, 28 (Supp. 1), 5.

- Chen, B., Lewis, M. J., & Grandison, A. S. (2014). Effect of seasonal variation on the composition and properties of raw milk destined for processing in the UK. Food chemistry, 158, 216-223.

- Azeze, T., & Haji, B. (2016). Assessment of post-harvest loss of milk and milk products and traditional mitigation systems in Southern Ethiopia. Assessment, 48.

- Abebe Bereda, A. B., Mohammed Yesuf Kurtu, M. Y. K., & Zelalem Yilma, Z. Y. (2014). Handling, processing and utilization of milk and milk products in Ethiopia: a review.

- Zelalem, Y. 2003. Sanitary conditions and microbial qualities of dairy products in urban and peri-urban dairy shed of central Ethiopia. LAMBERT Academic Publishing, pp: 85.

- Bussmann, R. W., Gilbreath, G. G., Solio, J., Lutura, M., Lutuluo, R., Kunguru, K., ... & Mathenge, S. G. (2006). Plant use of the Maasai of sekenani valley, Maasai mara, Kenya. Journal of ethnobiology and ethnomedicine, 2, 1-7.

- Sidigia, I., Nyaigotti, C. & Kanunah, M.P. 1990. Traditional Medicine in Africa. East African Educational Publishers, Nairobi.

- Onyango, C. A., Gakuya, L. W., Mathooko, F. M., Maina, J. M., Nyaberi, M. O., Makobe, M., & Mwaura, F. (2014). Preservative effect of various indigenous plants on fermented milk from Maasai community of Kajiado County. Journal of Applied Biosciences, 73, 5935-5941.

- Fita, L., Beyene, F., & Hegde, P. B. (2005). Traditional milk and milk products handling practices and preservation methods in three districts of East Shoa Zone of Oromia. ESAP Proceedings, 185.

- Getaneh, D., Banerjee, S., & Taye, M. (2019). Morphometrical traits and structural indices of malle cattle reared in the South Omo Zone of Southwest Ethiopia. International Journal of Veterinary Sciences Research, 5(2), 32-47.

- Kothari, C. R. (2004). Research methodology: Methods and techniques. New Age International.

- Alemu, T., & Girma, M. 2018. Indigenous knowledge on preservative plants and preservation techniques of milk and milk products in South Wollo Zone, Northern Ethiopia. International Journal Avian & Wildlife Biology, 3(2), 120-124.

- Lemma, F. 2004. Assessment of butter quality and butter-making efficiency of new churns compared to smallholders’ butter-making techniques in East Shoa Zone of Oromia. Alemaya University MSc thesis: Alemaya University.

- Getaneh, D. (2023). Assessment of Dairy Production System, Handling, Processing and Utilization Practices in South Ari and Malle District of South Omo Zone, Ethiopia. Research on World Agricultural Economy, 4(1), 10-24.

- Abebe B, Zelalem Y, Ajebu N 2012. Handling, processing and utilization of milk and milk products in Ezha district of Guragie Zone, Southern Ethiopia. Journal of Agricultural Biotechnology and Sustainable Development, 5(6):91-98.

- Azeze, T., & Haji, B. (2016). Assessment of post-harvest loss of milk and milk products and traditional mitigation systems in Southern Ethiopia. Assessment, 48.

- Kassahun Melesse, K. M. (2013). Sources of milk products, milk and milk products handling preservation and spices added to the milk products in Ada'a woreda, Ethiopia.

- Tigist, T. 2021. Milk Production and Reproductive Performance of Local and Crossbred Dairy Cows in Woreta Town, South Gondar Zone of Amhara Region. MSc Thesis. Bahir Dar University. Pp. 52.

- Sale, A., Dehinenet, G. & Zemenu, Y. 2018. Handling, Processing, Utilization and Marketing System of Milk and Milk Products in HuetEju Enesie District, East Gojjam Zone, Ethiopia. Journal of Biology, Agriculture and Healthcare, 8 (7), 33-48.

- Fikernehe, N., Estefanos, T & Esayas A. 2012. Production, handling, processing, utilization and marketing of milk in the Mid Rift Valley of Ethiopia, Chali Yimamu and Feyisa Hundessa. Adami Tulu Agricultural Research Center.

- Shambel, Z., Kebede, E., Mengistu, M., & Lamboro, T. (2021). Identification and Evaluation of Preservative Plants on Traditionally Fermented Cow Milk. Current Research in Nutrition and Food Science Journal, 9(1), 329-337.

- Admasu, L. 2020. Study on Dairy cattle production systems, Milk quality and major disease problems in Debre Berhan milk shed, central highlands of Ethiopia. PhD, dissertation. Addis Ababa University, Ethiopia. Pp. 175.

- Tewodros, A. & Muluken, G. 2018. Indigenous knowledge on preservative plants and preservation techniques of milk and milk products in south wollo zone, northern Ethiopia. International Journal of Avian and Wildlife Biology, 3: 120-124.

- Azeze, T., & Tera, A. (2015). Safety and quality of raw cow milk collected from producers and consumers in Hawassa and Yirgalem areas, Southern Ethiopia. Safety, 44.

- Gagara, M. H., Sessou, P., Dossa, F., Ahounou, S., Azokpota, P., Youssao, I., ... & Farougou, S. (2019). A study on the indigenous methods of processing milk in Niger. Current Agriculture Research Journal, 7(2), 213.

- Abraha, N. 2018. Handling, processing and utilization practices of milk products in Raya, the Southern highlands of Tigray, Ethiopia. Scho J. Food & Nutrition, 1(1): 9-15.

- Abebe, B. 2018. A Smallholder Dairy Production Characteristics, Microbial Quality and Safety of Raw and Fermented Milk, and Butter across the Value Chain in Addis Abeba and Asella Milk Shed. PhD Dissertation, Haramaya University, Haramaya, Ethiopia.

- Lencho Getechew Kebede, L. G. K., & Seblewongel Ayichew Megerrsa, S. A. M. (2018). Assessment of dairy farmers' hygienic milking practices and awareness on cattle milk-borne zoonoses in Bishoftu, Ethiopia.

- Shija, F. (2013). Assessment of milk handling practices and bacterial contaminations along the dairy value chain in Lushoto and Handeni districts, Tanzania (Doctoral dissertation).

- Yilma, Z. (2010). Quality factors that affect Ethiopian formal milk business; experiences from selected dairy potential areas. Addis Ababa, Ethiopia. Netherlands Development Organization (SNV).

- Aysheshim, B., Beyene., F. & Eshetu., M. 2015. Chemical composition and microbial quality of cow milk in urban and peri-urban area of Dangila town, Western Amhara Region, Ethiopia. Global Journal of Food Science and Technology, 3(1): 81-85.

- Blowey, R., & Edmondson, P. 2010. Mastitis Control in Dairy Herds 2nd ed CABI (Centre for Agriculture and Biosciences International) Publishing.

- Gemechu, A. T. (2016). Assessment of safety and quality of raw whole cow milk produced and marketed by smallholders in central highlands of Ethiopia. Assessment, 49, 63-71.

- Chamberlain, A. 1990. An Introduction to Animal Husbandry in the Tropics. 4th ed. John Wiley and Sons INC., New York. pp. 758.

- Gatwech, T. 2012. Dairy Production, Processing and Market System: A Case Study of Gambella, South West Ethiopia. MSc Thesis, Addis Ababa University, Ethiopia.

- Happy, B. & Kanyeka 2014. Assessment of Microbial Quality of Raw Cow’s Milk And Antimicrobial Susceptibility Of Selected Milk-Borne Bacteria in Kilosa and Mvomero Districts, Tanzania.

- Jayarao, B. M., Pillai, S. R., Sawant, A. A., Wolfgang, D. R., & Hegde, N. V. (2004). Guidelines for monitoring bulk tank milk somatic cell and bacterial counts. Journal of dairy science, 87(10), 3561-3573.

- Sisay, L. 2018. Assessment of Cow’s Milk Hygienic Practices under Small Scale Farmers in West Hararghe Zone, Oromia National Regional State, Ethiopia. Advances in Life Science and Technology, 68: 46-55.

- Galmessa, U., MeseretKumela, A. B., & Fita, L. (2019). Gender Roles in Dairy Cattle Production, Processing and Marketing in Two Selected Districts of West Shoa Zone of Oromia Regional State, Ethiopia. EC Agriculture, 5(12), 01-14.