Archive : Article / Volume 2, Issue 2

- Research Article | DOI:

- https://doi.org/10.58489/2836-5127/010

Effect of Ozone Layer Depletion on Advanced Materials

- Indian Institute of Science (IISC)-INUP &VVIT

- Vasireddy Venkatadri Institute of Technology

- Mallareddy Engineering College (MREC-A)

- Annamalai University

- Mallareddy Engineering College

- NRI Engineering college

Alla Srivani

Dr Alla Srivani, GVS Subbaroy Sharma, M. Srinivasa Rao, P Ramesh, A Raghavendra, G Krishna Kumari, (2023). Effect of Ozone Layer Depletion on Advanced Materials. Journal of Radiology Research and Diagnostic Imaging. 2(2). DOI: 10.58489/2836-5127/010.

© 2023, Alla Srivani, this is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

- Received Date: 30-01-2023

- Accepted Date: 06-02-2023

- Published Date: 09-02-2023

ozone layer, advanced materials, uv-b, economic loss

Abstract

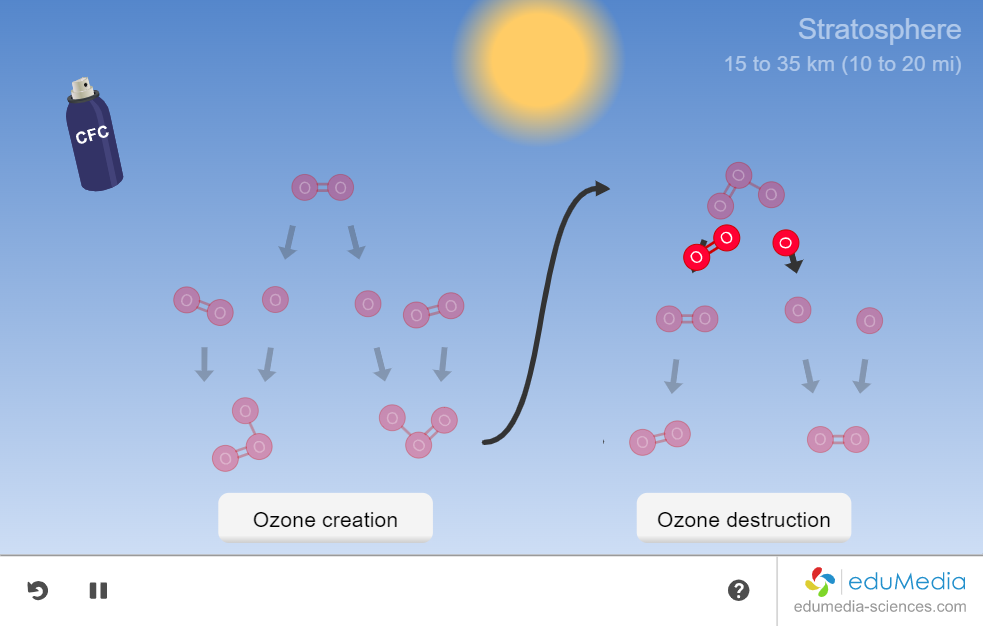

From ozone exposure can result in significant economic losses due to the higher costs of maintenance, upkeep, and replacement of these materials. Common plastic materials' outdoor service life is restricted by their vulnerability to sun UV radiation. The UV-B component of the solar spectrum is highly effective in causing photo damage in manufactured and naturally occurring materials. This is especially true with plastics, rubber, and wood utilised in the construction and agriculture industries. Any drop in the stratospheric ozone layer and resulting increase in the UV-B component of terrestrial sunlight will therefore tend to reduce the service life of these materials. However, estimating the extent to which the service life is shortened is challenging because it is dependent on various factors.

Introduction

Wavelength sensitivity of a variety of popular plastic materials and natural biopolymers is accessible, and the damage (per photon) often decreases exponentially with wavelength. Despite the considerably higher fraction of UV-A in sunshine, UV-B content accounts for a significant portion of light-induced material degradation.

The principal mitigation strategy is based on the efficacy of existing light stabilisers (such as hindered amine light stabilisers, HALS) used in plastics exposed to extreme solar UV conditions, as well as climate change considerations.

Research Method

The harsh weathering environment created by the simultaneous action of increased UV-B levels due to ozone depletion, as well as the relevant climate, are taken into account when developing advanced light-stabilizer technologies, more light-resistant grades of common plastics, or surface protection technologies for wood.

Solar UV light degrades the characteristics of organic building materials such as polymers and wood. The rates of degradation of these materials under solar UV radiation, as well as other climate conditions such as temperature, moisture, and atmospheric contaminants, influence their outdoor service lifetimes. While the stratospheric ozone layer is predicted to regenerate, local increases in UV radiation are still likely, particularly in the tropics, but also elsewhere due to climate change effects.

When combined with rising ambient temperatures as a result of climate change, such changes can dramatically reduce the service lifetimes of organic building materials. Several tried-and-true technologies, such as the use of UV stabilisers, surface treatments, or coatings, have been developed over the years to help with this.

Nano scale inorganic fillers with typical particle sizes an order of magnitude are already commercially available. The efficacy of these fillers in polymer compositions, notably their role as photo stabilizers, is being studied. Depending on the surface coating of the particles or their chemical makeup, these may increase or retard photo degradation.

Recent research suggests that they can be used as excellent photo stabilizers in a variety of polymers. However, the potential negative interaction of nano scale fillers with other additives in the formulation has also been mentioned. Nano fillers may provide a helpful way to UV-stabilization of plastics and rubber used outdoors, depending on the efficiency of stabilisation and the economics of their use.

Despite the slightly diminished engineering qualities of these composites, their cost advantage makes them appealing. According to recent findings, the photo stability of these composites is dependent on the source of fibre as well as the processing procedures used to make goods from them.

Results

Identification of the key factors of polymer-wood composites in terms of species, isolation, and processing is crucial for developing them for long-term outdoor use.

Efforts to synthesise novel light stabilisers, particularly those based on hindered amine light stabilisers (HALS), as well as to develop synergistic combinations of known stabilisers for common thermoplastics, are ongoing.

Recently, HALS-type stabiliser variants that minimise stabiliser loss via leaching or migration were reported. Despite the slightly diminished engineering qualities of these composites, their cost advantage makes them appealing. According to recent findings, the photo stability of these composites is dependent on the source of fibre as well as the processing procedures used to make goods from them.

Identification of the key factors of polymer-wood composites in terms of species, isolation, and processing is crucial for developing them for long-term outdoor use. Efforts to synthesise novel light stabilisers, particularly those based on hindered amine light stabilisers (HALS), as well as to develop synergistic combinations of known stabilisers for common thermoplastics, are ongoing. Recently, HALS-type stabiliser variants that minimise stabiliser loss via leaching or migration were reported.

UV radiation, which consists of photons with a high energy relative to visible light, can cause degradation in vulnerable materials in the form of physical and chemical changes. UV degradation is an issue for manufacturers and users of a wide range of materials designed for use and storage outdoors and thus exposed to sunshine.

Conclusion

As a result, because UV has such a substantial economic impact, published data on material degradation by UV is nearly entirely related to that present in sunlight at the earth's surface.

The ability of UV-C light to penetrate materials will depend on the chemical composition of the materials. Most acrylic plastics will allow light of wavelength greater than 375 nm to pass through the material, but they will not allow UV-C wavelengths (100–290 nm) to pass throughUV light (UV) is the single most important cause of fading in fabrics, carpets, and other furnishings.

Although visible light, electric lighting, temperature, humidity, fabric age, and fabric colours all have a role, UV radiation is responsible for 40% of the damage.

References

- Ackman, R.J. (1968). The flame ionization detector: Further comments on molecular breakdown and fundamental group response. J. Gas Chromatogr. 6:497—501.

- Adams, R.M., S.A. Hamilton, and B.A. McCarl. 1985. An assessment of the economic effects of ozone on U.S. agriculture. J. Air Pollut. Control Assoc. 35:938—943.

- Adams, R.M., J.D. Glyer, S.L. Johnson, and B.A. McCarl. 1989. A re-assessment of the economic effects of ozone on U.S. agriculture. J. Air Waste Manage. 39:960—968

- Adams, R.P. 1989. Identification of Essential Oils by Ion Trap Mass Spectroscopy. San Diego, Calif.: Academic Press, Inc. 302 pp.

- AFGL (Air Force Geophysics Laboratory). 1985. Atmospheric composition. Pp. 21-1 in Handbook of Geophysics and the Space

- Environment, A.S. Jursa, ed. Air Force Geophysics Laboratory, Air Force Systems Command, United States Air Force.

- Aimedieu, P. 1983. Ozone profile intercomparison based on simultaneous observations between 20 and 40 kin. Planet. Space Sci. 31:801—807.

- Akimoto, H., K. Takagi, and F. Sakamaki. 1987. Photoenhancement of the nitrous acid formation in the surface reaction of nitrogen dioxide and water vapor: Extra radical source in smog chamber experiments. Int. J. Chem. Kinet. 19:539—551.

- Albritton, D.L., S.C. Liu, and D. Kley. 1984. Global Nitrate Deposition from Lightning. Proceedings of the Conference on the Environmental Impact of

- National Academies of Sciences, Engineering, and Medicine. 1991. Rethinking the Ozone Problem in Urban and Regional Air Pollution. Washington, DC: The National Academies Press.